Bài học hôm nay bao gồm bài viết và video dưới sự hướng dẫn của Mr James với các đề Writing Process khó nhằn trong những năm qua. Các bạn cùng tham khảo học nhé.

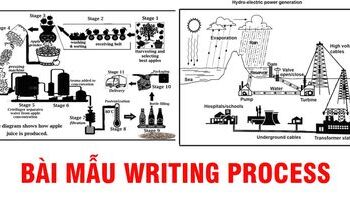

Writing Process: Apple juice

The diagram below shows how concentrated apple juice is produced.

Summarize the information by selecting and reporting the main features and make comparisons where relevant.

Write at least 150 words.

Brainstorming

- Overview:

Steps 1 - 4: preparing the ingredient

Steps 5 - 8: main parts, complicated technologies

Steps 9 - 11: packing and distribution

- Body:

Body 1: steps 1 - 4

Body 2: steps 5 - 8

Body 3: steps 9 - 11

Bài mẫu

The provided diagram illustrates how the process of producing apple juice takes places.

In general, this process includes 11 steps in which the first four steps involve preparing the ingredient, the next four steps are the main parts with complicated technologies, and the last 3 steps include packaging and distribution.

Specifically, the preparatory stage begins with harvesting and selecting the best apples from the trees. After going through an automatic belt and being washed and sorted at step 2, the apples are sliced in an apple grinder at step 3. Next, the apple slices are stored in a wooden bucket.

At stage 5, the apple slices are put into a pressing machine where water is separated from the apple by a centrifuge. Afterwards, the apple goes through a system of boilers and pipes where aroma is added. Steps 7 and 8 involve filtration and pasteurization at 80 degrees Celsius respectively.

At step 9, the apple juice is poured into bottles which are previously labeled. At the two final steps, the bottles are packed into cardboard boxes before being delivered by lorries, and the process finishes at this step. (188 words, band 7.0)

Vocabulary highlights

- preparation [n]: sự chuẩn bị / preparatory [adj]: mang tính chất chuẩn bị

- slice [v, n]: thái lát mỏng / 1 lát cắt

- bucket [n]: cái xô

- centrifuge [n]: máy ly tâm

- boiler [n]: nồi hơi

- pipe [n]: ống dẫn

- filtration [n]: quá trình lọc / filter [v]: lọc

- pasteurization [n]: sát khuẩn

- label [v, n]: dán nhãn / nhãn mác của sản phẩm

- cardboard [n]: bìa

- deliver = transport [v]: vận chuyển

- lorry = truck [n]: xe tải

Steps 7 and 8 involve filtration and pasteurization at 80 degrees Celsius respectively.

The first step in the process involves harvesting and selecting the best apples.

Subject: 1 hoặc 1 số các bước nào đó trong quy trình

Verb: involve / include

Objects: cụm V hoặc cụm N.

Writing Process: Geothermal

The diagram below shows how geothermal energy is used to produce electricity.

Brainstorming

- Overview: movement and heating of water: absorb geothermal energy => convert into electrical energy

- Body 1: movement of water to absorb geothermal energy

- Body 2: conversion into electrical energy

Full sample

The provided diagram illustrates how the process of generating electricity in a geothermal power plant happens.

Overall, this process includes 6 steps in which the movement and heating of water plays an essential role. Water absorbs geothermal energy and converts it into electrical energy.

Specifically about the movement of water to absorb geothermal energy, the process commences when cold water from a tank on the surface is pumped to the depth of 4.5 km underground. Then, the water goes through an injection well into a geothermal zone where it absorbs heat energy from hot rocks. At the third step, after receiving sufficient geothermal energy, boiling water is pumped upward back to the surface through a production well.

In terms of energy conversion, on the surface, boiling water is stored in a condenser. The higher the temperature, the higher the pressure, so high-pressure steam created in the boiling process is released from the condenser to turn the turbines. Then, a generator which is powered by the turbines produces electricity. Finally, electrical power is transmitted into the national grid, and the process finishes. (182 words, band 7.0)

Vocabulary highlights

- Geothermal power plant [n]: nhà máy điện địa nhiệt

- Geothermal energy [n]: năng lượng địa nhiệt

- Heat energy [n]: nhiệt năng

- Electricity = Electrical energy [n]: điện năng

- Convert [v] / Conversion [n]: chuyển hóa năng lượng

- Commence [v]: start, begin

- Inject [v] / Injection [n]: bơm/ tiêm/ phun (chất lỏng) vào đâu đó

- Absorb [v]: hấp thụ

- Sufficient [adj]: đủ cho 1 mục đích nào đó = Adequate

- Condenser [n]: buồng ngưng

- Power: [n] năng lượng; [v] cung cấp năng lượng cho cái gì đó hoạt động

- Transmit [v] / Transmission [n]: truyền tải (điện, tín hiệu v.v)

Writing Process: hydroelectric

The diagram shows how electricity is generated by a hydroelectric dam.

Summaries the information by selecting and reporting the main features and make.

Brainstorming

- Overview: 2 main parts, circulation of water + transmission of electrical power

- Body:

Body 1: circulation of water

Body 2: transmission of electricity

Full sample

The provided diagram illustrates how the process of generating electricity in a hydroelectric power plant happens

In general, the entire process can be divided into two main parts, namely the circulation of water and the transmission of electrical power.

Specifically, the process begins with the natural, repeating cycle of water. Due to the heat of the sun, water on the surface of the ocean evaporates resulting in the formation of clouds. Then, a dam is constructed on a slope to create an artificial reservoir where rainwater is stored. When the reservoir’s valve is opened, water is released. Its potential energy is converted into kinetic energy which turns the turbine to generate electricity. Afterwards, the water is pumped back to the reservoir against gravity, while the valve is closed to store water.

Regarding the transmission of electricity, we can see that it goes through a system of high voltage cables which are placed on towering electrical poles from the power station where electricity is generated to a transformer station. Next, it is transmitted through underground cables into homes, factories, hospitals, and schools. (181 words, band 7.0)

Vocabulary highlights

- Hydroelectric power plant [n]: nhà máy thủy điện

- Circulation [n] = Cycle [n]: vòng tuần hoàn; Circulate [v]: di chuyển theo một vòng tuần hoàn

- Transmit [v] / Transmission [n]: truyền tải (điện, tín hiệu v.v)

- Evaporate [v]: bay hơi

- Slope [n]: 1 con dốc / 1 sườn dốc của đồi, núi

- Artificial [adj]: nhân tạo

- Reservoir [n]: hồ chứa nước

- Potential energy [n]: thế năng

- Kinetic energy [n]: động năng

- Gravity [n]: trọng lực

- High voltage cable [n]: đường dây điện cao áp

- Towering [adj]: very tall

- Electrical pole [n]: cột điện

- Power station [n]: nhà máy phát điện

- Transformer station [n]: trạm biến áp

- Underground cable [n]: dây cáp ngầm dưới lòng đất

Writing Process: A lead pencil

Đề bài: The diagram below shows the production of a lead pencil.

The given flow chart illustrates the process of manufacturing a graphite pencil. In general, the process comprises two primary phases, which may be further categorized into eleven individual components. The procedure commences with the planting of seedlings and concludes with the packing of the finished pencils.

In the first stage, seeds are cultivated in soil for a period of four months before being transplanted to different locations. After a period of three years, these trees undergo a process of thinning and are thereafter left undisturbed for a duration of 14 years. As reaching full maturity, the trees are harvested and transported to a plant for further processing.

Cutting equipment is used at the plant to slice the trees into slender slats prior to undergoing a treatment procedure. Following a two-month period, the wooden sheets have acquired cut grooves and have been supplemented with glue. The black leads are positioned between two slats. A heated and compressed machine is used to shape the freshly assembled sandwiches. Subsequently, the material is sliced into elongated cylindrical shapes. During the subsequent phase, the pencils undergo a process of being coated with various colors, sharpened, stamped, and then prepared for packaging. Ultimately, the items are easily available for delivery to customers.

Writing Process: Pineapple

The method depicts the phases and equipment used in the manufacture and shipment of pineapples for final retail sale.

The natural development process has four stages, from little crowns to ripening fruits. Once collected, pineapples go through a manufacturing process that begins with preparation and size-based categorization and ends with three separate products: juice, canned pineapples, and whole fruits for export.

The natural process begins in tropical areas with temperatures ranging from 23°C to 30°C. Pineapples are grown using crowns throughout this phase, and after 7 months, ethaline is applied to assist the fruits achieve their maximum size for an additional 5 months. Pineapples are collected at different heights ranging from 26cm to 30cm (2kg).

In terms of production, the pineapples are thoroughly cleaned before being divided into three types. The smaller and medium-sized ones have their tops removed and their rinds peeled. The former is then run through a juice extractor to make juice cartons, while the latter are sliced and ready for canning. Meanwhile, the 30-centimeter pineapples go through a simpler procedure of wax coating, packaging into cartons, and lastly shipping by freight overseas.

Writing Process: Chocolate

The diagram below shows the process for the making of chocolate.

The images illustrate how to manufacture chocolate in industrial scale

Overall, the process includes several steps, beginning with the materials and ending when the liquid chocolate is produced.

The whole operation starts with the cocoa trees, which plays a vital part in this procedure and thrives in South America, Africa and Indonesia. When the pods are ready to be harvested, they will turn red or yellow. This is the time for the farmers to collect and split the shells into half by hands using machetes. All of the accumulated beans are going to experience the fermentation step inside banana leaves to get rid of thick and sticky white pulps covering the main ingredients. Before being put into sacks and weighed, these materials have to be thoroughly dried under the sun for a certain amount of time, which solely depends on the weather. And they will be loaded onto trucks or lorry, ready to get shipped.

Arriving safe and sound at the destinations, all of the bags will be stored in warehouses. The first process they have to go through inside the factory is roasting, conducted in a giant oven at around 360 OC. This will improve the flavour of the beans, preparing it for the next step : crushing and removing the outer shells. The former procedure will be done with a huge roller, while the worker will use the technique called winnowing to complete the latter stage. By simply pressing the inner part, the chocolate liquid is formed. This fluid are ready to be turned into various products such as bars, candy.

Trên đây là bài mẫu IELTS Writing Task 1 Process với các dạng đề khó, các bạn cùng tham khảo, tự viết nâng cao kỹ năng của bản thân nhé.